Kubadthal, Ahmedabad, Gujarat

- GST NO. : 24ARSPB7610A1Z9

Packaging Machine

Leading Manufacturers, Exporters, Wholesaler and Trader of 20 Liter Blow Moulding Machine, Batch Coding Machine, Blow Molding Machine, Bottling Machine, Cap Sleeve Applicator Machine, Jar Filling Machine, Jar Washing Machine, Shrink Wrapping Machine and Sticker Labeling Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | HB INTERNATIONAL |

| Finishing | Polished, Chrome Finish, Coated |

| Raw Material | PET |

| Driven Type | Electric |

| Machine Body Material | Stainless Steel |

| Shape | Rectangular |

| Color | SS CROME |

| Condition | New |

| Automatic Grade | Automatic |

| Frame Design | Closed Frame |

| Speciality | Reliable, Easy To Use, High Efficiency |

| Usage | Blow Molding, 5 LITER TO 20 LITER PET JAR BLOWING |

| Certification | ISO 9001:2011 |

| Voltage | 220V 3 PHASE |

| Production Capacity | DEPENDS ON BOTTLE OR JAR SIZE |

| Type | Stretch Blow Molding |

| Warranty | 1 Year |

| Air Consumption | REQUIRE AIR COMPRESSOR |

| Country of Origin | India |

| Model | Hb-20l 120 Sbmm-4/1000 |

| High Pressure Seal Cly. Dia | 125 X 60mm Strock - 01 No. |

| Stretch Rod | Dia : 25mm With Gripper For Single Cavity Jar. |

| Mould Clamping Cylinder | 30 Ton 350 Stroke |

| Sealing Nozzle | Inner Type For 12ltr Jar Dispenser 120mm Neck |

| Delivery Time | ONE MONTH AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

Capacity :

- Production Range 5 Ltr Capacity 250 - 300 Jar Per Hour

- 10 Ltr - 15 Ltr 150 To 160 Jars Per Hour

- 20 Ltr Capacity 110 - 120 Jph

- (Product Weight 675 To 710 Grms)

- 20 Ltr Capacity 140 - 150 Jph

- (Product Weight 350 Grms For 1 Way Disposable Jar)

- (Depending On Molds And Preform Quality)

Tech. Spec. :

- Infrared Conveyorised Preheating System - 950mm Two Modules 3980mm Long (3 Ph)

- Fully Pneumatic Conveyor With Online Inner Heating System

- Mould Clamping Cylinder 30 Ton 350 Stroke

- Plc Base Touch Screen Type Controller Model Ultra Cpu 09

- Preform Indexing Bonfiglioli Gear Motor With Ac Variable Drive

- Preform Holder - 02 Sets (Bubble Top & Dispenser 120mm Neck)

- High Pressure Seal Cly. Dia 125 X 60mm Strock - 01 No.

- Blowing Valve Parker Lucifier

- Poppet Type Combine Low Pressure & High Pressure Blowing Manifolds

- Sealing Nozzel Inner Type For Bubble Top Jar - 1 No.

- Sealing Nozzel Inner Type For 12ltr Jar Dispenser 120mm Neck

- Stretch Rod - Dia : 25mm With Gripper For Single Cavity Jar.

- Combination Sealing & Stretching Attachment 25mm Stretch Dia With Gripper

- To Maintain Preform Uniform Preheating Provide High Efficiency Fan Behind The Heating Module.

- Set Of Tools And Operation Manual For Hydro Pneumatic Andmicroprocessor

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Model Number | HBI INK-JET 3000 |

| Capacity | AS PER REQUIREMENT |

| Specialities | Rust Proof, Durable, High Performance, Easy To Operate, Cost Effective |

| Brand Name | HB INTERNATIONAL |

| Driven Type | Electric |

| Shape | Rectangular |

| Condition | New |

| Operating Type | Automatic |

| Automation Grade | Automatic |

| Usage | Pouch Printing, Printing Batch Number, PRICE PRINTING MACHINE |

| Certification | CE Certified |

| Packaging Type | Wooden Box |

| Air Pressure | NOT REQUIRED |

| Type | Batch Coding Machine |

| Phase | Single Phase, Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| environmental protection | IP43: Stainless Steel Cabinet |

| Message Storage Capability | 50 |

| Print Heads | 1 |

| Inks | Dye Based |

| Maximum Lines of Print | 3 |

| Maximum Line Speed (1) | 146 m/min (482 ft/min) |

| Core Life (Maintenance Interval) | Up to 6000 hours |

| Umbilical Length | 6.56ft (2 m) |

| Smart Cartridge™ | Included |

| USB | Included |

| Display (User Interface) | 320x240 Bright Blue Backlit display |

| Delivery Time | ONE WEEK AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING. |

Preferred Buyer From

| Location | Worldwide |

WE ARE ONE OF THE MOST LEADING MANUFATURER SUPPLIER AND EXPOTER OF ALL TYPES OF MINERAL WATER TRATMENT PLANT, FILTERATION SYSTEM, PACKAGING MACHINERY, OZONATOR, OXYGEN CONCENTRATOR AND CHEMICAL.

OUR PRODUCT RANGE SERVES FROM COMMERCIAL AND INDUSTRIAL REQUIREMENT

Benefits of Ink Jet Printer Speed and quality

One of the better solutions for a range of slow to moderate speed applications:

- Upto 146 m/min (482 ft/min) for 1 to 3 line printing

- Single line: 5x5, 5x7, 7x9, 12x16, 16x16

- Double lines: 5x5, 5x7

- Three lines: 5x5, 5x7

- Store upto 50 complicated messages, limitless storage with USB. Standard USB with mark and memory back up function

- Small and portable, the Willett 630 is easily moved from line to line with minimal connections

Uptime Advantage via

- For upto 6000 hours of operation, no preventive maintenance is needed.

- At 3000 hours there is a prior maintenance reminder, which recommends the user to replace the cartridge after operating for 6000 hours.

- This capability eliminates the need for replacing dirty filters.

Superior Printing Quality

- The Willett 630 inkjet printer can accurately locate every drop of ink within the cartridge, which makes the printed characters precise and easy to read.

- Even under rapidly changing print environment conditions, its dynamic calibration capability can calibrate automatically, ensuring consistent printing quality.

Simple Usability

- Bright blue backlit display with WYSWYG screen message editing

- Diaphragm type keypad with touch screen feedback, including 72 letters, numbers and keys of special function

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | HB INTERNATIONAL |

| Finishing | Coated |

| Raw Material | PET |

| Driven Type | Electric |

| Machine Body Material | Stainless Steel |

| Shape | Rectangular |

| Color | AS PER REQUIREMENT |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Speciality | Reliable, Easy To Use, High Efficiency |

| Usage | Blow Molding |

| Certification | CE Certified |

| Type | Stretch Blow Molding |

| Warranty | 1 Year |

| Air Consumption | REQUIRE AIR COMPRESSOR |

| Country of Origin | India |

| Container Capacity | 200 ml to 2000 ml |

| Output Rates | Up to 1600 BPH |

| Delivery Time | ONE MONTH AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

Semi Automatic Blowing Machine is suitable to produce different shape of the PET Bottles. The USP of this machine is it could blow containers from 200 ml to 2000 ml and thus gives the user the flexibility to blow such a wide range on the same machine.

Features & Advantages

- Fast Machines with output rates up to 1600 BPH thus optimizing productivity and production cost

- Precise heat control due to layered heating system

- Reduced electrical consumption: reflectors are close to the preform in the oven

- Preform Feeder Reliability: speed regulation loop from the elevating column to the orientation

- Parts changed less frequently : parts are more robust, with optimized service life

- OMRON PLC with touch screen keypad

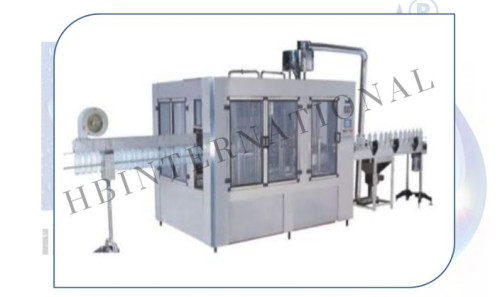

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Material | Steel |

| Main Motor | 2 Hp |

| Conveyor Motor | 1 Hp |

| Air Conveyor | 1 Hp |

| Shrink Tunnel | 4 Kw. |

| Cap Elevator | 0.5 HP |

| Filling Tank Capacity | 180-200 Liter. |

| Washing and Filling Pump | 0.5 Hp |

| Washing and Filling Pump Make | Lube , C.R.I , CNF etc. |

| Filling Range | 200 ml To 1000 ml. |

| Machine Out Put | As per client Requirement |

| Main Motor Make | Rotomotive, C.G, Bonvareo etc. |

| Gearbox Make | Chamunda, Rotomotive etc. |

| H.M.I and P.L.C Make | Delta, Kinko etc. |

| Electric Component make | Select, Semen’s etc. |

| Machine Dimension | 2620 mm x 1800 mm x 2550 mm |

Preferred Buyer From

| Location | Worldwide |

We Are Manufacurer AUTO & SEMI-AUTO Bottling Machine That Produce 60-200 Bottle Per Minute.

Salient Features

- Machine over load protection with mechanical clutch +VFD Protection

- Bottle Catching & all star wheels below the neck only

- Instruction & Indications Systems

- All Machine parts With CNC Made

- Programmable Logic Controls

- Rinsing Water pressure Interlock

- Filling Water Tank low & High Level Inter lock

- Cap feeder Cap empty single

- Bottle Filling Level Set with Mechanical vent tube

- In feed air blower conveyor SS 304 Hepa Filter with UV

- All material SS 304 & contact Parts SS 316

- Cap Hopper Elevator type & having capacity of 3000 caps at a time

- Out Conveyor SS 304 , conveyor belt also SS 304

- Oil Central Lubrication Systems

- Pneumatic :- Festo OR SMC of Janatics

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | HB INTERNATIONAL |

| Material | SS 304 / SS 316 / SS 316 L |

| Driven Type | Electric, Mechanical |

| Color | SS CROME |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Semi Automatic |

| Application | SLEEVE LABELING MACHINE |

| Certification | CE Certified, ISO 9001:2011 |

| Feature | PROVIDE HIGH SPEED AND HIGH QUALITY SLEEVE LABELING |

| Voltage | 220V, 3 PHASE |

| Custom Order | WE ACCEPT CUSTOM ORDER |

| Warranty | 1year |

| Country of Origin | India |

| Model | HBI - 100/200/300 |

| Sleeve Roll Outer Dia. | 400mm |

| Height of Conveyor** | 860-910 mm |

| Electrical Rating | 1.5KW-2KW, 380V AC, 50/60HZ, 3-Phase |

| Output/Min.* | Up to 300 |

| Delivery Time | ONE MONTH AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

Shrink Sleeve Applicator Machine - HBI/200/300 is design to insert sleeve with desired position of various size and shape of containers. This unique model is suitable for variety of industries with an opportunity to reduce labour and increase manufacturing rates.

The machine having integrating functions of delivering & classifying containers, accurate cutting of label sleeving and proper positioning of sleeve on bottle.

HBI - 100/200/300 is constructed on sturdy welded steel frame completely enclose in S. S. Sheet doors and aluminium alloy.

The unit consisting of Sleeve roll loader—carrier assembly, Conveyor bottle separating assembly, Centre pillar, Bottle positioning mechanism, Cutter mechanism, Optical scanner, Controlling assembly and Brush assembly etc

This Shrink Sleeve Applicator Machine model operates with great simplicity, high efficiency and minimal maintenance with production capacity up to300BPM.

Salient Features: Shrink Sleeve Applicator

- Rigid Structure constructed S. S. and anodizing aluminium alloy.

- Fully automatic machine with speed up to 300 BPM.

- No bottle no sleeve.

- Statics charges elimination system for accurate sleeve placements

- Totally PLC control system.

- No tools required for changeovers from one size bottle to another.

- Servo based high speed with accurate length sleeve feeding and rotary sleeve cutter systems

- Online speed can vary 8: fully synchronized with all mechanism.

- Suitable for various shape of Glass, Plastic, Pet, Tin, Corrugated containers.

Optional Features: Shrink Sleeve Applicator

- Sleeve Label Roll Empty : Machine stop with Alarm.

- Missing sleeve label : Machine stop with alarm or online pneumatic operated product rejection system.

- Tower light: Indicate the status of process.

- Depends on container and sleeve label size.

- Can be supplied as per customer requirements.

- Specification can be altered as per customer specific requirement.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | HB INTERNATIONAL |

| Material | Stainless Steel |

| Finishing | Chrome Finish |

| Color | SS CROME |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | CE Certified |

| Voltage | 220V 3 PHASE |

| Capacity | AS PER REQUIREMENT |

| Packaging Type | Carton Box |

| Type | Filling Machine |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Machine Structure | Horizontal |

| Filling Valve Head | Multi-Headed |

| Delivery Time | ONE MONTH AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDED HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

WE ARE ONE OF THE MOST LEADING MANUFATURER SUPPLIER AND EXPOTER OF ALL TYPES OF MINERAL WATER TRATMENT PLANT, FILTERATION SYSTEM, PACKAGING MACHINERY, OZONATOR, OXYGEN CONCENTRATOR AND CHEMICAL.

OUR PRODUCT RANGE SERVES FROM COMMERCIAL AND INDUSTRIAL REQUIREMENT

Features :

- Neck holding

- No bottle no rinsing no filling and no capping

- Single stage rinsing (final water)

- Non contact sensors

- Separate cap Hopper having capacity 50 Caps

- Material of contractions contact parts SS316L rest SS304

Features :

- Neck holding

- No bottle no rinsing no filling and no capping

- Single stage rinsing (final water)

- Non contact sensors

- Separate cap Hopper having capacity 50 Caps

- Material of contractions contact parts SS316L rest SS304

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Brand Name | HB International |

| Material | SS 304 / SS 316 / SS 316 L |

| Driven Type | Electric |

| Color | SS CROME |

| Condition | New |

| Automatic Grade | Semi Automatic, Automatic |

| Application | WASH 20 LITER PET JAR |

| Certification | CE Certified |

| Voltage | 220V |

| Capacity | 80-100 JAR PER HOUR |

| Machine Type | SS |

| Bottle Size | 20 LITER [PET JAR |

| Type | Jar Washing Machine |

| Warranty | 1 Year |

| Country of Origin | India |

| Warrenty | 1Year |

| I Deal In | New Only |

| Washing Type | AUTOMATIC |

| Dimension | 4 fit h x 3.5 W x 3.2 fit L (2 head) |

| Normal Water Motor | 0.5 hp -2 no. |

| Panel (inbuilt) | 1 No Automatic |

| Inner & Outer Washer | PP Brush |

| Gear Motor | 0.25 HP |

| Delivery Time | ONE WEEK AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

WE ARE ONE OF THE MOST LEADING MANUFATURER SUPPLIER AND EXPOTER OF ALL TYPES OF MINERAL WATER TRATMENT PLANT, FILTERATION SYSTEM, PACKAGING MACHINERY, OZONATOR, OXYGEN CONCENTRATOR AND CHEMICAL.

OUR PRODUCT RANGE SERVES FROM COMMERCIAL AND INDUSTRIAL REQUIREMENT

|

MAKE |

HB INTENATIONAL |

|

DIMENSION |

4" FIT H X 3.5 W X 3.2 FIT L (2 head) |

|

TYPE |

CLOSE BODY TYPE |

|

NORMAL WATER MOTOR |

0.5 HP -2 NO. |

|

PANEL (INBUILT) |

1 NO AUTOMATIC |

|

INNER & OUTER WASHER |

PP BRUSH |

|

GEAR MOTOR |

0.25 HP |

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Operating Type | Semi Automatic |

| Material | Mild Steel |

| Warranty | 1 Year |

| Packaging Type | Carton Box |

| Finishing | Polished |

| Specialities | Rust Proof, High Performance |

| Usage | Industrial |

Preferred Buyer From

| Location | Worldwide |

After Completion of filling capping and labeling, product containers are being fed automatically to lane divider and start moving in a single lane form on the collating table in a matrix form. Required container pack matrix formation being done by collation through a pneumatic pusher, which after completion is transferred forward for the web sealer position.

Immediate after proposed matrix enters into web sealer, the welding bar activates to complete the wrap, and the pusher returns to prepare the next collation of product. As the welding bar ascends, the pusher advances to transfer the new collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor. Once proposed wrapped matrix enters the shrink tunnel chamber, re-circulated hot air causes the wrap to shrink and tightly conform to the contours of the contents. Once the pack comes out of the hot chamber, Air cooling is used to tighten sleeve wrap to achieve a strong, secure pack ready for stacking on pallet or a placing on a shipping carton.

In Semi Automatic Shrink wrap machine the pusher mechanism will be manual and respective specification and feature changes.

- Fully Automatic Shrink Packaging Machine Including Sleeve Sealer And Shrink Tunnel Which Can Feed Products, Collating, Seal And Cut Film And Shrink Film Bag Automatically. It Is Widely Used In Food, Pharmaceutical, Cosmetics, Printing, Hardware, And Other Industry.

- This Machine Can Collate Bottles (Round Or Square), Cans, Gable Cartons, And Tetra Cartons

- Automatically. It Can Connect Filling Machine Or Labelling Machine To Make Production Line Unmanned.

- Bottles Can Be Collated Faster By A Special Faster And Stable Collating Device And Never Fall Down.

- Adopt Durable "U" Shape Alloyed Sealing Knife And Saw Teeth Cutting Knife With Anti-stick

- Teflon Coats Supported By Four Columns, The Sealing Line Is Very Strong And Can Use Thicker Pe Film For Heavy Products.

- Rows Can Be Set On The Touch Screen. When Product Size Changes Only Adjust Packing Size On The Machine Within A Short Time Without Changing Any Molds.

- Adopt Siemens Plc And Colorful Touch Screen, Omron Temperature Controller, Timer, Relay,

- Switchs & Sensor.

- Optional Output Roller Table Or Conveyors Are Available.

- Optional Safety Cover Is Available.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Material | SS 304 / SS 316 / SS 316 L |

| Brand Name | HB INTERNATIONAL |

| Driven Type | Mechanical, Electric |

| Color | SS CROME |

| Condition | New |

| Automatic Grade | Semi Automatic, Fully Automatic, Automatic |

| Application | Industrial |

| Certification | CE Certified |

| Voltage | 220V 3 PHASE |

| Type | Sticker Labeling Machine |

| Weight | 3000-4000kg |

| Warranty | 1year |

| Country of Origin | India |

| Packaging | Wooden case |

| Operating System | Automatic |

| Delivery Time | ONE MONTH AFTER GETTING 50% ADVANCE PAYMENT |

| Packaging Details | WE PROVIDE HIGH QUALITY EXPORT GRADE PACKAGING (CHARGES ARE EXTRA) |

Preferred Buyer From

| Location | Worldwide |

WE ARE ONE OF THE MOST LEADING MANUFATURER SUPPLIER AND EXPOTER OF ALL TYPES OF MINERAL WATER TRATMENT PLANT, FILTERATION SYSTEM, PACKAGING MACHINERY, OZONATOR, OXYGEN CONCENTRATOR AND CHEMICAL.

OUR PRODUCT RANGE SERVES FROM COMMERCIAL AND INDUSTRIAL REQUIREMENT

Item Description:

Ø SS conveyor

Ø Top conveyor

Ø Separator

Ø Pressing device

Ø 0.5 hp motor & drive

Ø PLC based Control panel